The Ultimate Buyer’s Guide to Pallet Stretch Wrapping Machines

Every industrial buyer knows that when it comes to optimizing warehouse operations, the devil is in the details. The machinery you invest in can make the difference between a smooth operation and costly logistical nightmares. One such critical investment? Stretch wrap pallet machines. For those responsible for ensuring that goods are transported securely and efficiently, this tool is indispensable. If you’re pondering this investment, here’s an in-depth dive tailored for you.

Understanding the Urgency: Why Every Modern Warehouse Needs a Pallet Wrap Machine

Globalized supply chains, increasing consumer demands, and the necessity for rapid dispatch mean warehousing operations must be more efficient than ever. Damage during transit, caused by mishandling or the elements, can result in both financial losses and reputational damage.

A pallet wrap machine not only ensures products are securely contained but also optimizes the wrapping process to reduce time and material waste. It’s an investment in confidence, ensuring that every outgoing shipment is as secure as possible.

The Landscape of Choices: Types of Pallet Wrapping Machines

- Turntable Stretch Wrapper:

- Functionality: This is the model many are acquainted with. The pallet is placed on a rotating platform, and as it turns, stretch wrap is applied uniformly.

- Best Suited For: Businesses with standard pallet sizes and a regular dispatch routine. Also ideal for those transitioning from manual wrapping to automated systems.

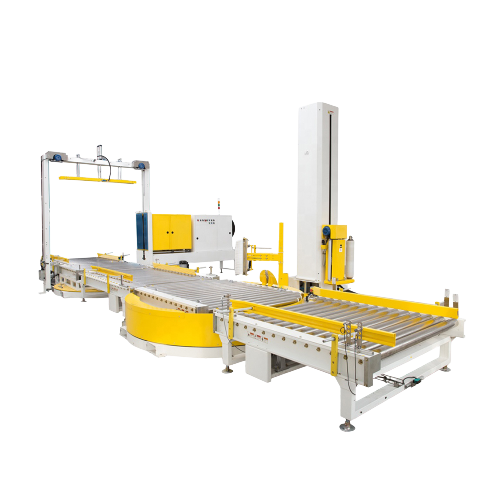

- Rotary Arm Stretch Wrapper:

- Functionality: The arm, not the pallet, does the moving. It encircles a stationary pallet, dispensing wrap as it goes.

- Best Suited For: Operations with heavy or uniquely shaped pallets.

- Robotic Pallet Wrapper:

- Functionality: Think of this as your mobile wrapping unit. It autonomously wraps pallets without them needing to be placed on a specific platform.

- Best Suited For: Dynamic warehousing environments with space constraints or varying pallet locations.

- Horizontal and Ring Wrapping Machines:

- Functionality: These handle the long, non-standard items with aplomb, wrapping them securely.

- Best Suited For: Businesses with non-standard items like timber, rods, or carpets.

Delving Deeper: Factors to Consider Before Investing

- Volume and Scalability: Assess your current needs but also anticipate growth. Your machine should serve you well into the future, not just meet today’s demands.

- Operational Speed: Time is money. Machines with faster wrap cycles can significantly enhance warehouse efficiency.

- Maintenance & Support: Investigate the machine’s maintenance requirements. Also, consider the manufacturer’s support system. Will they be available for maintenance, parts replacements, or if issues arise?

- Cost Implications: Beyond the upfront investment, consider the long-term cost implications. This includes maintenance costs, potential downtime, and wrap material costs.

- Space & Logistics: Evaluate your warehouse’s spatial constraints. Some machines might be bulkier than others or require specific setups.

- Training Needs: While most modern machines are user-friendly, there’s a learning curve. Factor in the time and resources needed for staff training.

ROI & Long-Term Benefits for the Astute Buyer

- Operational Efficiency: Automated wrapping means fewer manual hours and faster dispatch times.

- Damage Control: Well-wrapped pallets drastically reduce in-transit damage, saving on replacement costs and potential insurance claims.

- Sustainability & Waste Management: Efficient machines optimize wrap usage, which means reduced waste and potentially lower ongoing costs.

- Enhanced Business Reputation: Delivering consistently well-packaged goods enhances your business’s reputation for professionalism and reliability.

Incorporating Future Growth

Before making a purchase, consider the scalability of the machine. As your business grows, your wrapping needs might intensify. Investing in a machine that can handle higher capacities or has upgradeable components can be a prudent long-term decision.

Conclusion

For industrial warehouse buyers, investing in a stretch wrapping machine to wrap pallet loads is a strategic decision that impacts not just warehousing operations but also the broader business reputation. By understanding the nuances of available machines and aligning them with business needs, one can optimize operations, reduce costs, and bolster the bottom line. For any more questions or buying concerns dont hesitate to contact us here.

Will H.

Packaging Expert

will@packwrapdirect.com